CUSTOMIZING PLATINUM RECYCLING : FUTURE OUTLOOK ▶️

POSTED BY ALICE

Our third and final Atlanta presentation was made by Dr. Semih Sunkar from Nippon PGM, a joint venture between DOWA Metals & Mining Co., Ltd,. and Tanaka Kikinzoku Kogyo K.K.

DOWA, with a 60% share has expertise in smelting, base metals, and recycling, Tanaka, with 40% is well known for its refining capabilities.

Japanese-based, Nippon PGM is also established in USA and in the Czech Republic and the company has created a unique and environmentally sound PGM recycling process.

As a specialized PGM recovery operation, Nippon PGM is committed to cost-effective recycling and has developed its unique recycling process. Rather than using smelters, that are involved in the recovery of many other metals, to process autocatalysts, Nippon uses an electro arc furnace (EAF) and an oxidation process to recover the PGMs. This is a patented technology, dedicated only to PGMs which has low running costs, zero hazardous waste, and leaves a low carbon footprint. The Tanaka side of the business then takes over, with its customized PGM recycler, a fully automated process with short lead times and high yield. Given its heavy investment in this process, Nippon PGM understandably has a vested interest in future developments within the automotive industry…

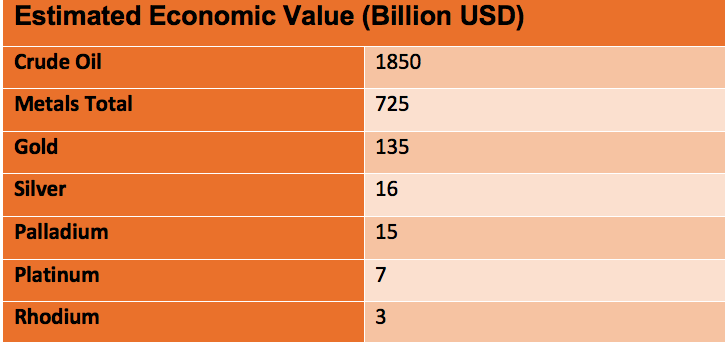

PGMs in Context (2018)

This demonstrates that PGMs, whilst important to all of us, is only a very small fraction of the total metals market, which in turn is dwarfed by the value of crude oil.

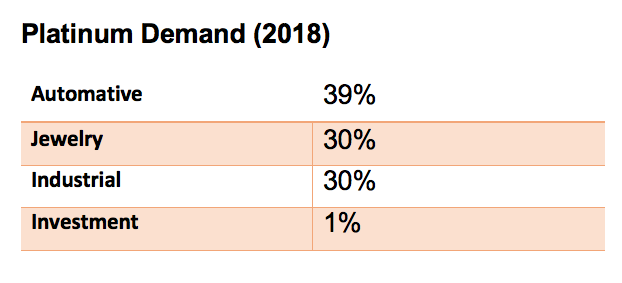

In the space of just 40 years, the automotive industry has become the dominant user of platinum, and the mainstay of the metal’s demand growth.

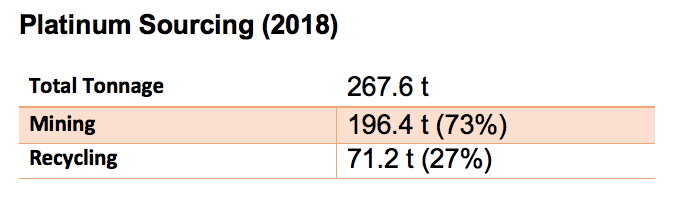

Recycling is now a proven contributor to the supply of platinum, and, at a time when there is increasing concern over the eroding of the earth’s resources, recycling offers a more sustainable route. The success of autocatalyst recycling can be attributed to 4 factors:

- Established a recycling scheme

- Competitive and innovative collection

- Simple design, making extraction of the precious metals relatively easy

- Available and dedicated processing infrastructure

Recycling Business Model

Now an established industry, the recycling process typically involves a “food chain” of 4 operating levels:

GENERATOR: Local traders, scrap yards, family-run businesses that are the source of the catalysts. Cash-orientated.

TRADER: Regional businesses, profit-orientated, working on a “fast retail” model

PROCESSOR: Multi-national operators with extensive know-how, highly results-orientated.

REFINER: Global businesses with high levels of professionalism and expertise, product-orientated.

Business Evolution - A Nippon View

Evolution of Catalysts

1975 - Two Way Catalysts (first introduced in USA)

1983 - Three Was Catalysts

1991 - Metal Foil Catalysts (resulting from Euro 1)

2003 - DPF Cordierite (resulting from Euro 3)

2010 - DPF Silicon Carbide (resulting from Euro 5)

2018 - DPF Aluminates (resulting from Euro 6)

2025 - Electric Vehicle boom…?

2030 - New Materials…?

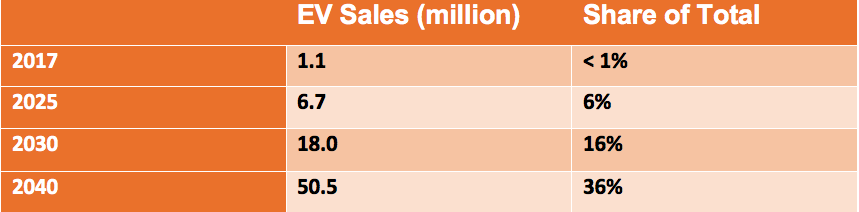

There are various forecasts on the impact that Electric Vehicles will have, and equally importantly, what type of EV will prevail…

Fuel Cell Technology - is this the future?

Many are firm of the view that by the 2030s fossil-fuel cars will become rare, with battery and hydrogen-powered vehicles come to the fore.

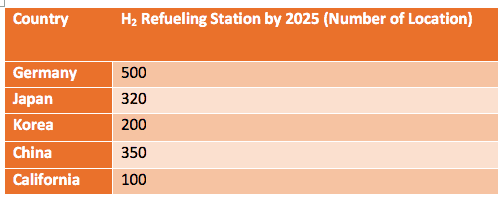

Presently BEV technology is leading the way and forecasters suggest that by 2050, it will control 75% of the vehicle market. Fuel cell technology, though, is favored for larger vehicles and for the longer driving range and is becoming a cheaper option as technology improves. And there certainly is a great deal of interest and investment in the technology with industry giants including Daimler, Hyundai, Toyota, Audi, and Michelin amongst many others, having already announced initiatives in just the past 6 months. As well, some countries and states have already stated targets for H2 refueling stations by 2025:-

PGM Impact

The outcome of this “war” between battery and fuel cell power has major significance for platinum because only fuel cells require catalysts. The key issue for the PGM recycling industry is whether fuel cells can be re-used or whether it is more practical to recycle the platinum. The latter has key advantages that need to be exploited

- Speed of processing

- Established sampling and processing technology

- Clear regulations and control

- Established network and expertise

- Low purchasing capital required

Conclusion

It is likely that fuel cell technology is the prime opportunity for the future of platinum recycling. We need to encourage investment in this technology, improve the recyclability of fuel cells, and be ready technically to meet the demand.